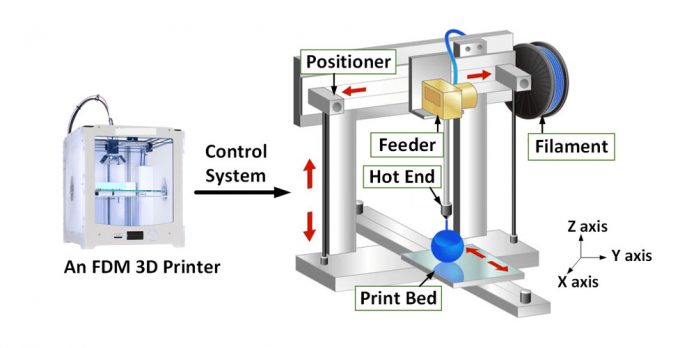

3D printing is one of the most popular manufacturing techniques on the market. It is used for manufacturing a wide range of products in varying industries. Organizations also use 3D printing for making prototypes and concept models for testing. 3D printing is a general term featuring several printing techniques and types of printers. For instance, FDM 3D printers are a popular type of 3D printer. This post covers the FDM 3D printing process and everything you need to know about it.

What is FDM 3D printing?

Scott Crump developed the FDM 3D printing technique in the 1980s. It is a 3D printing process that applies production-grade thermal plastic material to produce 3D objects. The method is quite popular because it helps create manufacturing aids, functional prototypes, and concept models. It has many applications as it uses a technology that can produce accurate details and extraordinary strength to weight ratio.

How does FDM 3D printing work?

The FDM 3D printing process is not as complicated as most people would assume. Below is a guide for how it works:

1. The FDM 3D printing process

As is the case with other 3D printing techniques, the first step is preparing the materials and the machine for the printing process. Here, you must slice the 3D CAD data. This is the 3D model. It is cut into multiple layers through special software.

The sliced 3D CAD model then goes to the printer, which constructs the object layer on the build platform. This is done by heating and extruding a thermoplastic filament through the printer nozzle. It goes onto the base.

From here, the printer then goes on to extrude the thermoplastic 3D printing filament onto the base. This is done through the nozzle also. In addition to the thermoplastic filament, the FDM 3D printer can also extrude other support materials. For instance, an upper support layer can be extruded to add exceptional support for the material beneath. Note that the support materials or coatings are usually designed to dissolve once the printing process is complete.

From there, the material will continue to extrude as the product is manufactured through additive manufacturing. Once the object is finished, it needs to be cleaned. More often than not, the raw FDM parts may show slightly visible layer lines. However, this may not be the case with all objects. In such cases, you will need to hand sand and perform some other finishing techniques on the product afterward. Doing this will provide you with a smooth end product. It will also ensure that the surfaces are even.

2. Products manufactured through FDM printing

FDM 3D printing can be applied for manufacturing a wide range of products. It also uses a wide range of printing materials. Examples of products manufactured through FDM 3D printing are mechanical engineering parts, plastic products, and objects in the food industry. Products made using this 3D printing technique boast both functionality and durability. They also feature varying sizes and qualities.

Conclusion

The amount of time the printing process takes to complete the FDM 3D printing process depends on the object’s size, as with other 3D printing techniques. It may also depend on the complexity of the object design.