In the ever-transforming landscape of modern manufacturing, one technology has proven to be a true industry disruptor: CNC machining. This groundbreaking approach to fabrication has not only revolutionized production processes but also challenged traditional manufacturing norms. Let’s dive deep into the core of this disruption and explore the profound impact of CNC machining on various industries.

Redefining the Manufacturing Paradigm

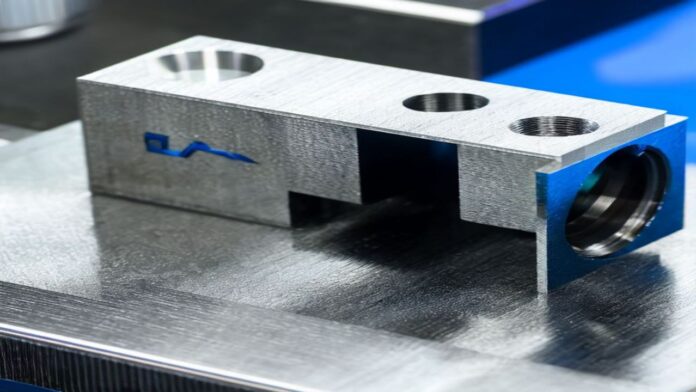

At the heart of CNC Machining Serviceslies its ability to bring automation and precision to the production floor. Unlike the manual techniques of the past, CNC machines are directed by computer programs, resulting in unparalleled accuracy and efficiency. This fundamental shift has not only increased productivity but also reduced material waste, translating into significant cost savings for manufacturers.

The Transformational Power of CNC Machining

The impact of CNC machining extends far beyond productivity gains. By allowing manufacturers to produce complex and customized designs effortlessly, this technology opens doors to a new era of creative possibilities. No longer constrained by manual limitations, designers and engineers can explore uncharted territories of innovation, fostering a culture of creativity that drives progress.

Reshaping the Workforce Landscape

As CNC machining continues to shape the manufacturing industry, questions arise about its potential impact on the workforce. Some fear that automation might lead to job losses, but the reality is more nuanced. While certain manual jobs may indeed be replaced, CNC machining also generates new opportunities for skilled workers. The key lies in equipping the workforce with the knowledge and skills to operate and maintain these advanced machines.

Embracing the Future with a Human Touch

As we embrace the technological marvel of CNC machining, it is vital to remember that technology is a tool, not a replacement for human ingenuity. The true essence of this industry disruption lies in the harmonious coexistence of man and machine. By fostering a learning environment that encourages innovation, we can harness the full potential of CNC machining to drive meaningful progress.

Sustainability and Social Responsibility

Beyond the immediate benefits, CNC machining also holds promise in promoting sustainability and social responsibility. By minimizing material waste and optimizing production processes, this technology contributes to reducing the environmental footprint of manufacturing. Moreover, cost efficiencies gained through CNC machining can translate into more accessible and affordable products for consumers.

A Journey of Continuous Improvement

The journey with CNC machining is not a destination but a continuous process of improvement. As technology evolves, embracing the latest advancements and integrating them into manufacturing practices will be crucial for staying competitive in the market. Additionally, investing in research and development will lead to even more innovative applications of CNC machining in the future.

Conclusion: Embrace the Disruption

In conclusion, CNC machining stands as a testament to human innovation and adaptability. By unlocking the power of automation, precision, and creativity, it has forever changed the manufacturing landscape. Embracing this disruption with a human touch, we can maximize the potential of CNC machining while fostering a skilled and empowered workforce. Together, let’s pave the way for a sustainable, innovative, and prosperous future for industries worldwide.