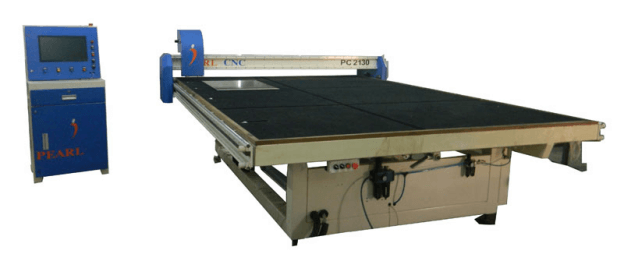

CNC glass cutters are very simple glass cutting machines used in a lot of industries for automated glass cutting. CNC simply stands for computer numerical control which simply means that the overall control of this machine relies on a lot of numerical and computer programming. Because of these programs, several industries have adopted the use of these machines. They are very important and it works very well with the combination of glass separating table and loading machine. The CNC glass cutter is known to deliver high precision and accuracy. In several glass industries, this glass cutter is one of the most preferred.

In this article, we are going to go through what the CNC glass cutter is, what it is used for, its pros and cons and why it is preferred.

WHAT IS THE CNC GLASS CUTTER AND WHAT IS IT USED FOR?

The CNC glass cutter is an automated glass cutter with has a thickness ranging from 3mm to 19mm respectively. The machine is controlled by special software that drives the operation and control. It is known to be very power efficient as very effective when it is used in the industry. In the CNC glass cutter, there are loaders incorporated in the machine. These loaders are used for placing the glass sheets on the cutting machine. On the machine, these loaders are placed in a vertical placement so that the cutting procedure will be easy. Most people love using this machine simply because, when compared to the manual machine, it is operated by the person controlling the program instead of so many hands. This aids to reduce labor costs. Another main reason why a lot of people and industries love using this equipment is because of the ability of the cutting head to be adjusted easily. Having this ability, the overall set up of the machine will be very easy. Maintaining this machine will also be easy due to the way the machine is built.

In the CNC glass cutting machine, all you need is the input from the personnel in charge of the software to write a program to cut the needed parts. It is very easy and simple.

PROS

- It is very reliable.

A good CNC glass cutter works very well to give you the very best results over time. However, regular maintenance is required.

- It improves the production rate.

When compared to the manual glass cutter, the CNC glass cutter does its job faster and it is very timely. Once all the parameters have been entered into the glass cutting machine, it does its work flexibly.

- It is safer.

A good CNC glass cutter is safe and less prone to industrial hazards and accidents.

CONCLUSION

CNC glass cutters are the best when it comes to getting the jobs done for you. If you are looking for a way to get these CNC machines at an affordable price, then the Shandong Care Machinery Technology has the best machines that can give you the best results for your industry.