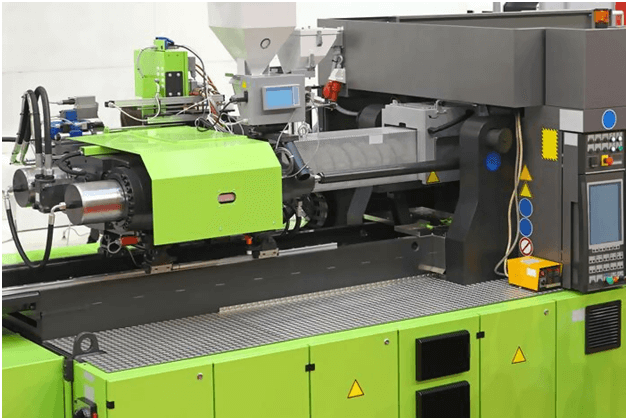

Plastic injection molding is the process where plastic raw materials are molded into a product. For example, if you want a baby doll, the manufacturer designs a mold of the puppet then pour the liquid plastic into that mold to form the doll. But, your manufacturer will use a plastic injection molding machine to mold electronics, auto parts, and kitchen supplies.

However, molding is not entirely restricted to plastic, but you can mold metal, glass, ceramic, and other materials too. So, if there is an electronic part that can’t be plastic, the manufacturer uses other ideal materials. Below are the various advantages of plastic injection moldings.

- Enhanced Strength

First, the plastic injection molding companies have to understand the environment in which the product will be used. Consequently, they will decide the strength required for the item and integrate the needed materials.

- Flexibility

Another advantage of plastic injection moldings is flexibility. If you want a plastic molding with a blue color, the manufacturer will find a resin with blue color. Consequently, he will identify an ideal material based on various variables like elasticity and strength.

However, ensure the resins used by the manufacturer complies with FDA, REACH and RoHS if the industry the product will be used requires the material to be certified.

- Reduced Waste

With the increased effects of global warming, a company manufacturing plastic products should have a recycling procedure put in place. The manufacturer should be concerned on the environmental impact of plastic moulding and find ways of minimizing negative impact.

Taking care of the environment starts with you, and therefore, you should find out how plastic manufacture uses waste. Fortunately, plastic waste can be recycled, thus; reducing waste.

- Low Labor Cost

Plastic injection molding is ideal for high production of affordable items. Once the injection molding process steps are set, there is no need to supervise it frequently. The plastic injection machine can produce high-quality products at high speed, which makes it easy to deliver the required items on time.

- Complex Part Design

Injection molding basics can help the manufacturer to design non-complicated items. However, there are various injection molding types, some of which are complicated. Nonetheless, plastic injection molding can achieve any design of an object.

- High Efficiency

Plastic injection molding is the fasted procedure as compared to other moldings. Therefore, it’s an efficient production process and thus cost-effective.

- Accuracy

One of the main advantages of injection plastic moldings is the ability to design the item to accuracy. A mold is cut into an ideal dimension before putting plastic pellets or liquid in the molding machine.

Take Away If you need kitchenware, electronics, and other plastic parts, consider hiring a company offering plastic moldings. Ensure the company is reliable and experienced by looking at their review page. Consider the technology they use to design and manufacture products. Also, confirm whether the plastic materials used are FDA, REACH, or NSF compliant.