Today’s steel business is not only limited to the movement of bricks. Offering a highly invaluable supply chain service is one of the best ways to survive in the near future. There is an intense demand for iron and steel business- it is raised to a level of understanding the astronomy from top to bottom. In this blog post, you will learn more about common slitting problems encountered when using slitter blades and other types of razors.

Common issues in the shearing processes are divided into transverse series, blanking series, in addition to equipment maintenance series. Secondly, burrs, winding staggered layers, and irregularities are additional problems you should be familiar with.

1. Describing burrs and cambers

Burrs and cambers are pretty much similar to the defects of major production lines. They resemble continuous retreat and hot rolling, usually found in a steel mill.

2. Burred edges

A burred edge is a relatively common defect in the metal shearing process. All too often, it is caused by the improperly gapped shear blade, which happens to be plain and dull.

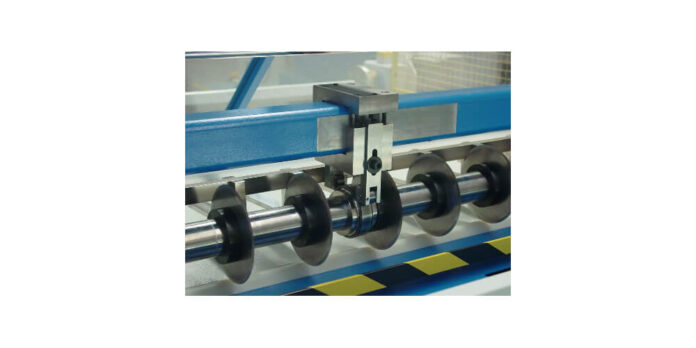

The gap found between the upper as well as lower blade is essential to the slitting process.

3. Burr-free

Extensive gaps will cause the edges to get torn. A small gap, on the other hand, will have a negative impact on the shear as it may fail to make it through the material especially due to the overload. Thus, ensure that you consult the metal and shear manufacturers’ operational manual to set an appropriate clearance for the machine.

4. Twist

Another common metal shearing challenge is the twist on the material. This can get better described as a tendency for the material to curl into a corkscrew immediately; it has been sheared. More prevalent in different sheared sections, the twist is caused by an excess rake angle.

If the shear has an adjustable rake angle, you should ensure that it is reduced to the minimum material type being sheared. Even though different properties of the said material may cause the twist, it is likely to be aggravated by intense rake angle.

5. Camber

Cambering is an additional issue or challenge created when the material in the sheering platform moves from the sheet without twisting.

Even though the issue is related to different stressors within the material, it is viable to reduce it by increasing the speed of RAM and changing the direction of grain being sheared by adjusting the angle of the rake of the material shearing where applicable.

6. Deformed Edges

Deformed edges can be caused by incorrect blade shear gaps coupled with dull, damaged blades. Also, an improper hold-down can also affect the blade. Thus, to rectify an incorrect blade, ensure that your gap is correctly set for the thickness of material you are using.

You also need to ensure that the blades are sharp and undamaged. Immediately you have checked the gap and blades, and made sure that they are sharp, you can check the hold downs and make sure that they are securely holding your material in place.

Finally, you should check the gibs of shears and ensure that the upper blade is clean.

Final Thoughts

Slitting line production is one of the primary ways of coil processing. With the existing upgrade of the industry, coupled with the rise in demand of customers on quality of products, expectations are rather put forward for the shear production line.