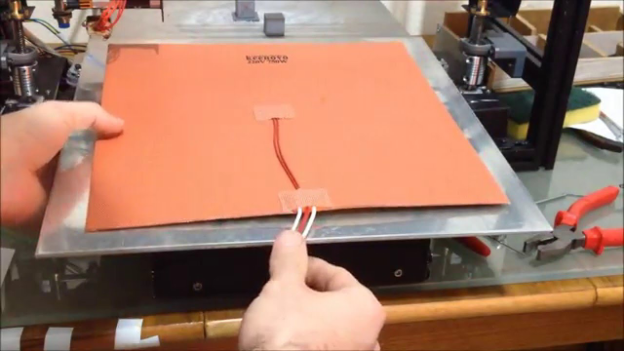

3D printing is the most convenient mode of mass production, as well as the fastest. The quality of work achieved by the printer depends on the functioning of its components. Such components include the quality of the 3D modeling software and the slicing software as well. Another element that affects the quality of the 3D printed object is the quality of the printing machine’s base. The print base refers to the first layer of deposited substrate on the printing machine. Using an inadequate 3D printing platform causes flaws in the printed items. Also, the quality of the 3D printing bed is influenced by the material from which it is made.

Types of 3D printing bed materials

There are several types of materials from which 3D printing plates are manufactured. Some of these materials include acrylic plastic and aluminum, which are conventional choices. However, some modern printers use more specialty materials, the likes of thermoplastic polyurethane, but the most commonly used material is glass.

Factors to consider when choosing the best 3D printing plate

Below are some elements that determine the best 3D printing plate:

- Thermal Fatigue Resistance

3D printing plates are subjected to high amounts of heat. The heat comes from the molten material used in printing and heating beds that are used in some situations. The best content for a printing plate would, therefore, be one with an incredibly low coefficient of thermal expansion. This means that the plate would not have to go through any form of physical changes when it is subjected to high temperatures. This element helps to keep the printed objects from adapting to the flaws of the plate. For instance, glass has a very low coefficient for thermal expansion, which makes it the preferable printing plate material.

- Physical strength

A printing bed should be strong enough to handle the physical conditions during the printing process. Some of these conditions include the heat and weight of the printed object. This means that the plate should not experience damages like breakage during printing, as it may affect the quality of the printed object.

- Flatness

The best type of printing plate should be consistently flat. Most printers feature settings that allow the user to adjust the flatness of the printing beds. However, it is more convenient to use a flat surface as opposed to constantly changing the settings, which can result in flawed prints.

- Easy print removal

Using the wrong type of printing bed would result in difficulties removing the prints from the print bed. Therefore, to avoid wastage of time and energy, it is vital to choose a printing plate that requires the least amount of removal effort. This element will help prevent damages to the final print object as well as the print plate.

Take Away

When determining the best print plate, it is also essential to choose one that is cost-efficient and easy to maintain. Of all the types of printing plates, the most beneficial is glass. The reason is that glass is durable, flat, cost-efficient, and easy to clean up, to mention a few.