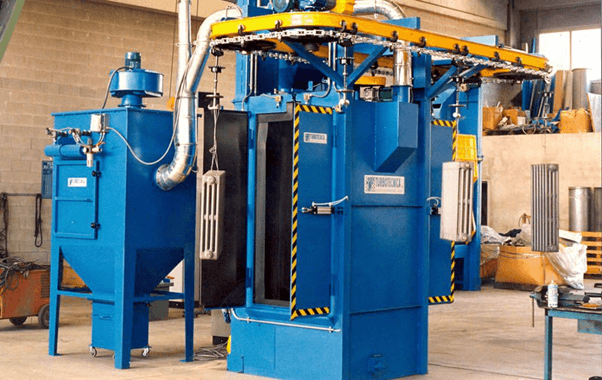

In the two previous sessions, we have learned that shot blasting is a metal cleaning process used in several industries. The machine used in blasting operations is an enclosed device for cleaning as well as preparing stone too. It is also the one used for shot peening coupled with cleaning various metal parts, including casting parts as well as heavy and sturdy metal structures. Let us consider the safety measures of a wheel blast machine.

You have also learned that a shot blasting machine uses a specific media on different metal parts, usually in an enclosed container. In this article, however, we shall focus more on the safety elements you should consider before using a blasting device. We will be more specific by looking at the wheel blasting machine.

Blasting is known as a specialized task that comes with several hazards. They may contribute to accidents, and there are also several risks involved with the blasting task. That is why before you begin blasting, you must consider the safety measures. Employers need to be familiar with the hazards before assigning an individual who can handle everything professionally.

The individual should be in a position to identify and recognize the significant dangers of the whole task. That way, they can be familiar with the risks associated with indulging in such tasks. A shot blast machine comes with several precarious issues that we shall address in the next paragraphs.

So, what are the safety measures?

- Provide Training To Employees

Employers need to provide training sessions for employees. The supporting personnel should be quick to grasp the lessons. Some of the practicals entail blasting health coupled with safety hazards regarding how to utilize as well as control personal hygiene practices.

It would be best if you also learned more about safe work practices. In this case, every blaster needs to wear a helmet coupled with safety glasses that play the role of protecting them against dust. The head of the blaster must also be covered from rebounding abrasive.

- Having An Overview Review Of The Area That Needs Blasting

Nothing beats the procedure of reviewing the area that will undergo blasted. Therefore, you need to consider the blast area before incorporating a security plan. This is because the area can be a risk potential for different materials. Air can cause injury without a doubt. So reviewing the area using a viable communication system will definitely be a safety measure towards creating a secure blasting environment.

- The Condition Of The Machine

It would be best if you made sure that the machine you are using is in perfect condition. Here, you should have a viable fuel system that is free from any form of leakage. The blaster needs to have extensive experience too.

Consider using a blast room in this case as it is one of the ways of enhancing the safety of an individual. Also, use restricted avenues specifically for the blasting operations.

Take-Home

Your blasting experience should definitely be engulfed in safety. That is why you need to consider weighing in the existing safety measures we have provided above. So, it would help if you incorporated less toxic shots in the process.