An automatic recirculation valve is also referred to as an ARC. This type of valve has the main function of ensuring that a predetermined volume of a particular liquid passes through a centrifugal pump at any given time. The automatic recirculation control valve helps to prevent centrifugal pumps from over-heating and being damaged permanently; this is what happens when the pumps run dry.

How the valves work to protect the pumps

A centrifugal pump makes use of centrifugal force and transforms mechanical energy into pressure energy. The energy created results from the rotation action of the impeller on the fluid that is inside the pump.

The centrifugal pump has to have a minimum liquid flowing through it so that it doesn’t overheat. If the volume of the fluid goes below a certain level, the pump gets damaged.

Let us have a look at different ways in which the valves work to protect the pump:

- No return scenario

In this case, the pump does not have back-flow prevention and so the fluid flows back once the pump is stopped. A non-return valve needs to be placed after the pump’s outlet.

Also, there’s a reservoir that takes the fluid when it’s not needed anymore.

- Continuous flow scenario

In this case, either a leakage path or a manual bypass is added to allow the required fluid to flow back into the pump’s inlet.

This system is a simple yet effective one. However, it’s always in constant operation which means that it’s not energy efficient.

- Control valve scenario

This type of system is highly effective. In this control valve, the flow meter is connected to the valve allowing the main flow to be metered.

Whenever the volume of the flow decreases, the control valve opens up to allow the right volume to pass through. This system is quite costly since it requires a highly capital intensive solution that comprises of control and non-return valves as well as flow metering equipment.

How the Automatic Recirculation Valve Operates

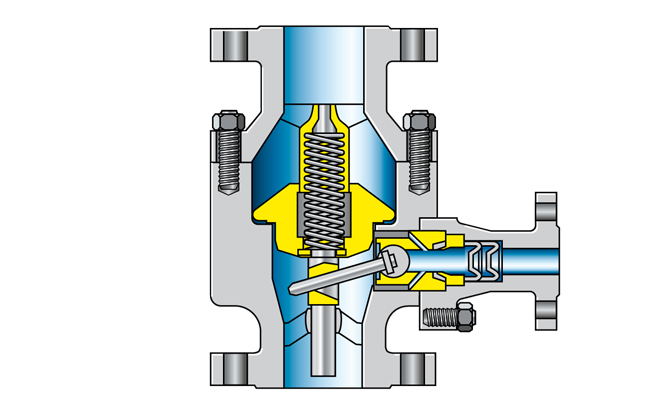

The heart of the automatic recirculation valve is a check valve disk that is used to sense the fluid’s flow rate. The valve disk is not pressure sensitive but rather flow sensitive. It controls the flow to ensure that a specified volume of the fluid passes through. The controlling characteristics result in a stable and consistent flow over a wide range of pressure.

- When the valve disk is at full capacity, the bypass closes. When the flow decreases, the action is reversed and there is an increase in the flow rate. The fluid then gets into the bypass system which is controlled by the orifices and is found at the bottom of the disk.

The fluid then flows through an annulus which directs it to an outlet.

- The increase in the flow of the fluid causes the disk to lift; as a result, the element of the bypass which is important for the functioning of the bypass closes to limit the recirculation. This ensures that the recirculation flow remains higher than the lowest volume of the fluid flowing through the pump.

- When the disk closes, the bypass opens fully and there is no fluid flow. This helps to protect the pump from damage that would result if the pump continued to operate and there was no fluid.