The concept of rapid prototyping is based on majorly on creating user-centered designs. This method has been used to create iconic products and is believed to be a big contributor to prototype manufacturing in Shenzhen. China Prototype does wonders in helping designers to make clients adopt their design ideas. When the client asks for evidence that the design will work, the designer can quickly produce a sample product to do a demonstration for the client. The client then gains confidence from the whole process because he/she is able to give feedback on where improvements need to be made and at the end of the day there will be guaranteed customer satisfaction.

Key benefits associated with rapid prototyping

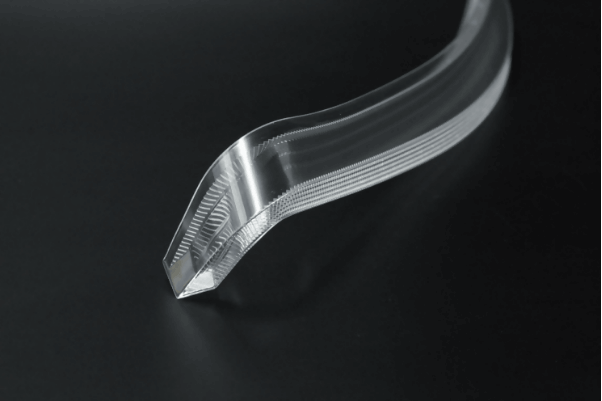

A major problem that manufacturers are faced with is that they find it hard to show a client how the end product will look and feel like. These aspects are quite hard to explain and prove using only models in software copy. This is where 3D printing comes in to save the day. The concept has gained popularity amongst manufacturers as they are now able to show clients the potential of the product in advance.

The main benefits of rapid prototyping are:

- Helps realize the design concepts

The technology makes it possible for designers to actualize the design concept beyond virtual visualization. So they do not have to work based on assumptions since they now understand how the design looks like and feels.

Rapid prototyping enables them to proceed with their design ideas and implement them before producing the final product. It also makes it very easy for the designer to provide proof of concept to the customers who are now looking for a more realistic design as opposed to a mere visualization on the screen.

- You can incorporate the changes instantly

Once the clients see the model, they can request for changes to be made to the design. The designer can make changes before creating the final product. This allows the design to improve even further to fulfill customer needs and at the same time helps the manufacturer to remain competitive.

- Saves resources, time, and costs

With 3D printing, the time, resources and costs are significantly reduced. Rapid prototyping is used to produce varying geometries. When it’s time to print, the product only uses the material that is required to build the product so the amount of waste is kept at a minimum.

- Personalized products

This is one benefit associated with rapid prototyping that we cannot overlook. The fact that it’s now easier and much more affordable to produce personalized products means that they are produced as per the customer’s requirements. This offers manufacturers huge benefits because the customers feel connected to them with every purchase made.

- Minimizes errors in the design

With rapid prototyping, designers can identify any mistakes in the design before production. The errors are identified during the testing so it becomes easy to avoid any issues that may arise later after mass production has already occurred.

Conclusion

Rapid prototyping provides designers with guidance on better ways of testing their concepts and coming up with new ideas. This greatly improves the relationship between the designers and the end-users. The structure of the 3D-enabled design process gives the users a satisfying experience that is a very important design concept on its own. It makes it easy for designers to enhance quality and adopt the probability of the final product.