Aluminum is one of the most popular fabrication materials in the market. This is because it is easy to shape. This characteristic can be attributed to its softness and lightness. Additionally, its properties can change if it is combined with other metals. The combination of aluminum with other metals results in the creation of alloys. Other properties like lightweight, corrosion resistance, and recyclability make fabrication processes like custom aluminum fabrication quite popular. In this post, we discuss various aluminum fabrication techniques.

The various aluminum fabrication techniques

Below are the basic fabrication techniques that can be used for aluminum;

1. Extrusion

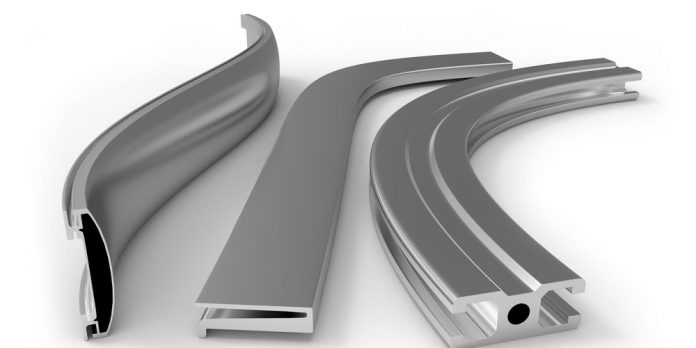

Aluminum extrusions are one of the most popular techniques of fabricating this metal. Its popularity can be attributed to the fact that it puts less stress on the metal. Extrusion works by forcing a piece of aluminum through a die. It can also go around the die, which can either be open or closed. This process causes the metal to conform to the physical characteristics of the die. The process can also be conducted with heated or room temperature metal.

2. Forming

Another popular fabrication method is forming. This method includes bending, stamping and rolling. It also involves pressing a part of the entire sheet or plate. Doing this helps create it into the desired product. It is an excellent fabrication method for aluminum because of its flexibility and softness.

3. Casting

Casting is a fabrication method where the metal is first heated to transform it into a molten form. Afterward, the molten metal is poured into a die or mold, where it is left to cool down and solidify. The mold is usually designed in the shape of the desired end product. Therefore, when the cool solidified product is removed from the mold, it has been transformed into the desired shape. Aluminum’s strength and wear resistance make it an excellent metal for this fabrication method.

4. Forging

This is a fabrication technique where the metal is either beaten or compressed into shape. This technique is best applied where the end products are meant to be incredibly durable. For instance, it is an excellent fabrication technique for making stress-bearing parts.

5. Machining

This is a subtractive fabrication technique where products are formed by removing parts of the metal. It usually involves processes like turning and milling. Machining of aluminum requires special tools and lubricants because of the metal’s specific thermal properties. These properties make it hard to use overall equipment.

Final word

There are several other fabrication techniques on the market. However, the methods mentioned below are more suitable for aluminum than waterjet cutting, adhesive bonding, and drawing. However, under special conditions, drawing can be applied as a fabrication technique for aluminum. Drawing is where the metal is pulled through a tapered die.

This movement stretches its forms of products like wires. It can also be used for making parts like cans. Drawing is a likely fabrication technique for aluminum because the metal is highly malleable. However, it may not work the same with aluminum alloys.