Shredding of paper is absolutely normal. Burning of plastic, not environmentally alright, but somewhat normal. Shredding of plastic on the other hand. How is that even possible? What does one need to shred plastic? The plastic shredder is one of the recent inventions that has actually made an impact on the environment. In its own way, it is an environmentally friendly invention. This is because it is extremely vital in the recycling process. The plastic crusher function and action are the major considerations for this article.

Plastic materials are very versatile and are used in a lot of manufacturing processes. So when it comes time for recycling, handling these plastic materials has always been an issue. But with the plastic shredder, that particular issue is done away with. After shredding recycling becomes so much easier.

What is a Plastic Shredder?

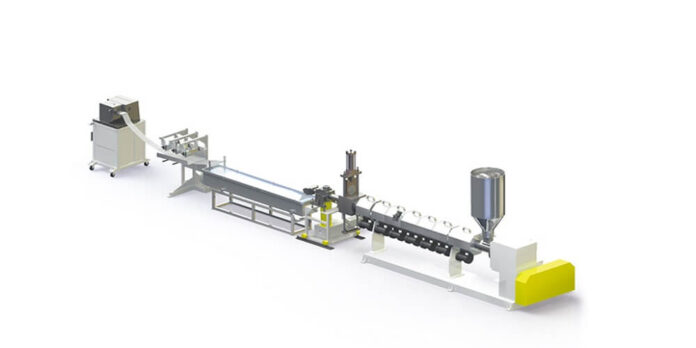

The plastic shredders are brilliant machines designed to handle the breaking sown or shredding of all sorts of plastic materials. From plastics derived from production waste to hollow parts plastics to fibers of various shapes and sizes and even PET bottles, the plastic shredder is designed to handle them all.

The plastic shredder is designed in such a way that it possesses various components and cutting edges. There are various models to ensure that regardless of the plastic involved, there would be an ideal machine.

How Exactly Does the Plastic Shredder Work?

The plastic shredder as mentioned earlier is composed of cutting edges. The design used in the plastic shredder puts in place a pretty effective “two-speed swing arm”. Then, we find a few rotors in place. For the standard plastic shredders, we observe a rotor diameter range of 400mm to 600mm; and a width range of 800mm to 3000mm.

Additionally, the hydraulic power unit of the machine is properly fitted into the plastic shredder` casing. This does not only protect it from unnecessary damage. It also serves to reduce the bulk of the machine (save space). Contrary to what some might think, this does not make maintenance any more complicated or difficult. Because, even though it is fitted in, it is still easily removable.

We also have a well-fitted S-type rotor and tool holder. These particular features are well commended by clients who already make use of plastic shredder. However, depending on what kind of plastic one might be shredding, these parts or components could be changed.

So far, we have mentioned a lot of the parts of the plastic shredder. However, not everyone understands how these components work. So to further break it down, let us make a comparison. Remember the way the paper shredder works? The plastic shredder works in the exact same way. Except the plastic shredder contains numerous shafts and varying knife designs. In short, the plastic shredder is much bigger and more powerful than the paper shredder.

Conclusion

Simply disposing of the plastic ends up doing more harm than good. So if one could get access to a plastic shredder it would be much more beneficial. For some large companies, making use of the plastic shredder could even save cost.